As published: Digital Twins for Project Planning and Management: Key Considerations

Digital twins are increasingly being employed to facilitate more efficient planning, design, and construction of new projects, and they can improve operations of the facility post-construction, as well. Digital twins provide a high-fidelity digital replica of a physical asset and can serve as an intuitive display of the extensive data sets required for a project. They encompass not only the design and engineering aspects of the project, but also its physical environment, economic neighborhood, construction process, and utilization and performance once complete.

To facilitate collaboration throughout the project, these data sets can be shared in whole or in part with the various constituencies, from developer to client or tenant. Data can be accessed in a range of formats from VR visualization of the entire project to mobile workflow apps that extract the detail needed by a subcontractor. The improvement in access to project data that digital twins allow results in a smoother process and lower project cost.

The Value of Digital Twins

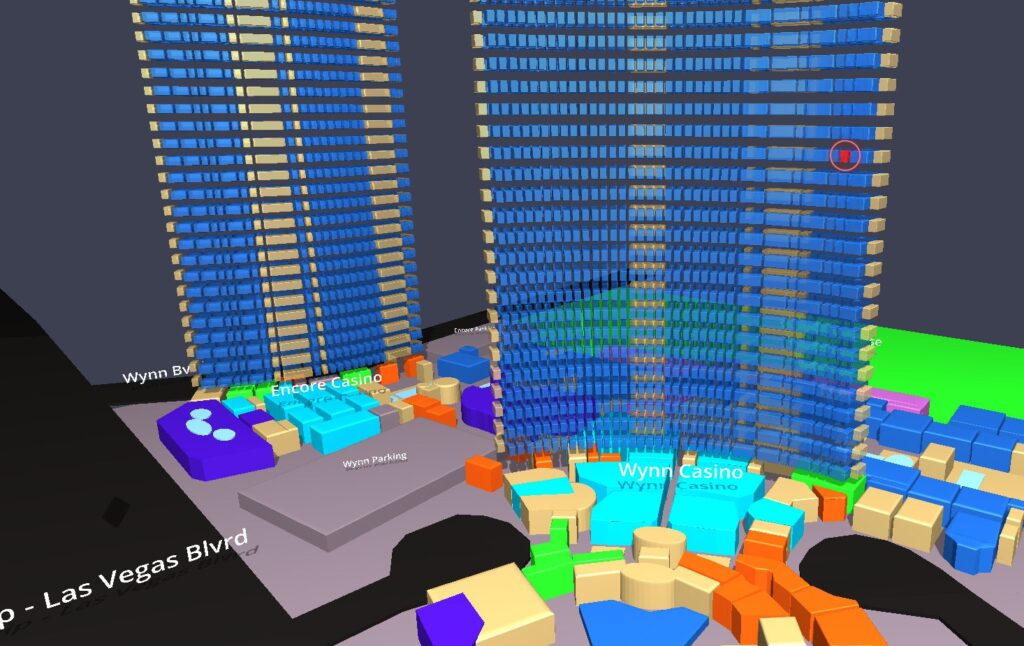

Geospatial data of a project site can contribute to a visualization of how the project fits into its environment. The ability to “walk around” the project in virtual reality provides visibility into how occupants and neighbors will experience the building, its impact on shadows and views, as well as accessibility. Many cities have begun publishing extensive data sets that include geo-referenced data (e.g. https://data.boston.gov/) ranging from flood risk from storm surges to snow emergency parking lots to food truck schedules, wind gust patterns during storms, and more. Each can be overlaid on the models to visualize various scenarios during the planning process. While these data sets have been readily available for years, they’re typically stored in formats that are not very user-friendly as standalone resources. Importing them into a digital twin yields a much more intuitive means of understanding the data.

During construction, a digital twin allows a distributed project team to work together seamlessly to monitor progress, visualize issues, implement change orders, or facilitate rapid response to unexpected events. By incorporating data from other management systems or sensors, digital twins are also able to show real-time project status including the number of workers at the site, deliveries, and the location of current or planned subcontractor activity within the facility. This shared view of the situation allows distributed teams to discuss options and resolve issues quickly without the need to travel to the physical site.

A great example of this is a large project management firm in Asia Pacific who recently used data from a digital twin to create a series of digital dashboards for its projects. These dashboards allowed for more frequent engagement and regular feedback from clients, and the process had many fewer major issues and cost overruns.

Once completed, a digital twin allows for visualization of the building or facility’s operating metrics captured from enterprise systems or IoT sensors. Examples of operating metrics include utility usage, utilization of parking lots, public spaces and restrooms, status of cleaning or maintenance activity, and location of portable shared equipment within the building. To create efficiencies, digital twin data analysis can improve lifecycle performance of materials and systems, enabling a process of systematic and continuous improvement for the benefit of future projects.

Deploying Digital Twins: The Data and the Dev Platform Are Everything

New multi-experience application development platforms greatly simplify the creation and use of digital twins. Such platforms significantly reduce the time and cost of digital twin creation, too. Multi-experience application development platforms also provide access across multiple device types – PC, mobile, or AR/VR headset, further promoting collaboration by different stakeholders. By using a multi-experience tool, one can easily create a visual presentation of project data customized to the specific needs of the client, architect, engineering team, and general and subcontractors. Multi-experience digital twin applications can also incorporate workflows, inspection, and approval processes as needed.

While these new dev platforms can simplify the process of creating digital twins and provide an intuitive, visual integration of project and contextual data, the value of the digital twin application is entirely dependent on two things: the data inputs used to generate the twin, and the flexibility of the dev platform to ingest and incorporate disparate data sets stored in many different formats. A development platform that can integrate and reformat a wide range of data formats – both CAD (computer aided design) files and data overlays – is essential to the development of a successful digital twin program.

Optimizing Data for Accuracy

The CAD and BIM (building information modelling) data sets of a new project are likely to be readily available. The detail of older structures undergoing renovation may not always be complete. CAD data for adjacent features such as buildings, streets and roads may be non-existent or out of date. Some schematics may exist only in paper plans or non-standard CAD formats. Digital twin platforms that can ingest dozens of types of CAD files and build 3D models from 2D data sets will greatly facilitate the project. Some CAD files can also be too detailed or complex for real-time renderings. Therefore, it is important to use a development platform that can intelligently transform files to lower resolution without losing critical details.

Geo-referenced data sets for data overlays come from a wide variety of sources including IoT sensors, municipal data, digital feeds from public data providers, or location-based workflow apps (such as inspection or approval processes). Some data may also be incomplete, contain errors, or reside in legacy systems with a nonstandard format. Wrangling the correct data is critical to developing an accurate digital twin platform. A generative system to synthesize missing data and conform outlying data is a key capability for success.

IoT data pipelines can be massive. Because of this, it is a best practice to use data transformation tools to aggregate and summarize the data for visualization. When doing this, unifying location across various data sets can be quite complex. To simplify the process, platform systems can unify data using 3D geofencing, point of interests, and GPS snapping systems.

Return on Investment of Digital Twins in Project Management

The initial effort in identifying and cleaning data sets is not insignificant, but it can be effectively managed with appropriate expectations and tools. If multiple projects are planned for a given area, using multi-experience development platforms becomes a valuable resource for future activity.

The cost of creating digital twins has been dropping, and they are expected to become a more commonly used project planning and management tool. The benefits of digital twins, including faster approval cycles, lower and more predictable construction costs, and greater client satisfaction, can greatly improve project economics. We see Digital Twins moving forwards as a fusion of real time, people-focused data sets and the traditional building and process-based BIM systems.